Ensuring Crew Safety: The Role of Ventilator Respirators in Military Aircraft

In the military, service personnel are exposed to threats every day – from in-flight emergencies such as smoke and rapid decompression, to the potential for encountering chemical, biological, radiological, or nuclear agents in hostile environments.

With the dynamic and ever-changing nature of the environments that military aircraft are sent to, it is critical that all equipment works properly and effectively to mitigate against future and unseen challenges.

One piece of equipment that often goes unnoticed but is critical in the line of defence is the ventilator respirator. Crucial in protecting aircrew against biological and chemical agents, ventilator respirators must be designed and delivered by engineers to precisely fit in a variety of aerospace applications.

Protection against invisible military aviation threats

Military aircraft, such as F35 Lightning II and Eurofighter Typhoon, travel at high-altitude, high-speed environments. Situations such as smoke from an electrical fire or a system malfunction can quickly escalate in these environments, putting pilots at serious risk.

As technological innovation continues and military aircrafts become more advanced, the potential for exposure to Chemical, Biological, Radiological and Nuclear Defence (CBRN) threats increases. Pilots therefore need immediate and reliable respiratory protection that goes far beyond oxygen delivery, to prevent the fatal condition of hypoxia.

Electro-mechanical and high-tech electronic equipment, like ventilator respirators, play a crucial role in ensuring pilot safety and survivability in the confines of the cockpit by filtering out hazardous contaminants and allowing pilots to maintain control of their aircraft. This is especially important in specific environments like the desert, where additional external threats can contaminate the airspace.

Key design considerations in ventilator respirator technology

Ventilator respirators must be designed to precise specifications depending on the aircraft, to ensure optimal performance. Key considerations during design include a secure facepiece or mask, filtered intelligent controlled airflow, and seamless integration with the existing communication system.

Pilots of fast jets require lightweight, low-profile systems that don’t impede their vision or movement during high-G manoeuvres, while still offering robust protection against decompression and potential airborne threats. Military respirators are often integrated within the aircraft’s oxygen supply system, providing emergency oxygen during decompression. Controlled airflow technology is also used to deliver a positive pressure flow of filtered air and enhances comfort during prolonged use.

The intelligent filtration system uses a multi-layered design to trap particulate matter. As industry-leading ventilator respirators, Castlet’s Mk. 9 and Mk. 8 Ventilator Respirator systems are specifically designed to filter out biological threats and neutralise chemical agents. The Mk. 9 maintains pressure as altitude increases, enabling a constant airflow for breathing at higher altitudes.

Another key consideration during design is where the aircraft is being sent – the anticipated operational environment and potential hazard ultimately impacts what type of system is fitted. They must be able to maintain durability even under G-force, high speed and extreme temperatures. Integration with modern aircraft intercoms is also vital to ensuring continued clear communication.

Why testing and training is crucial for military equipment

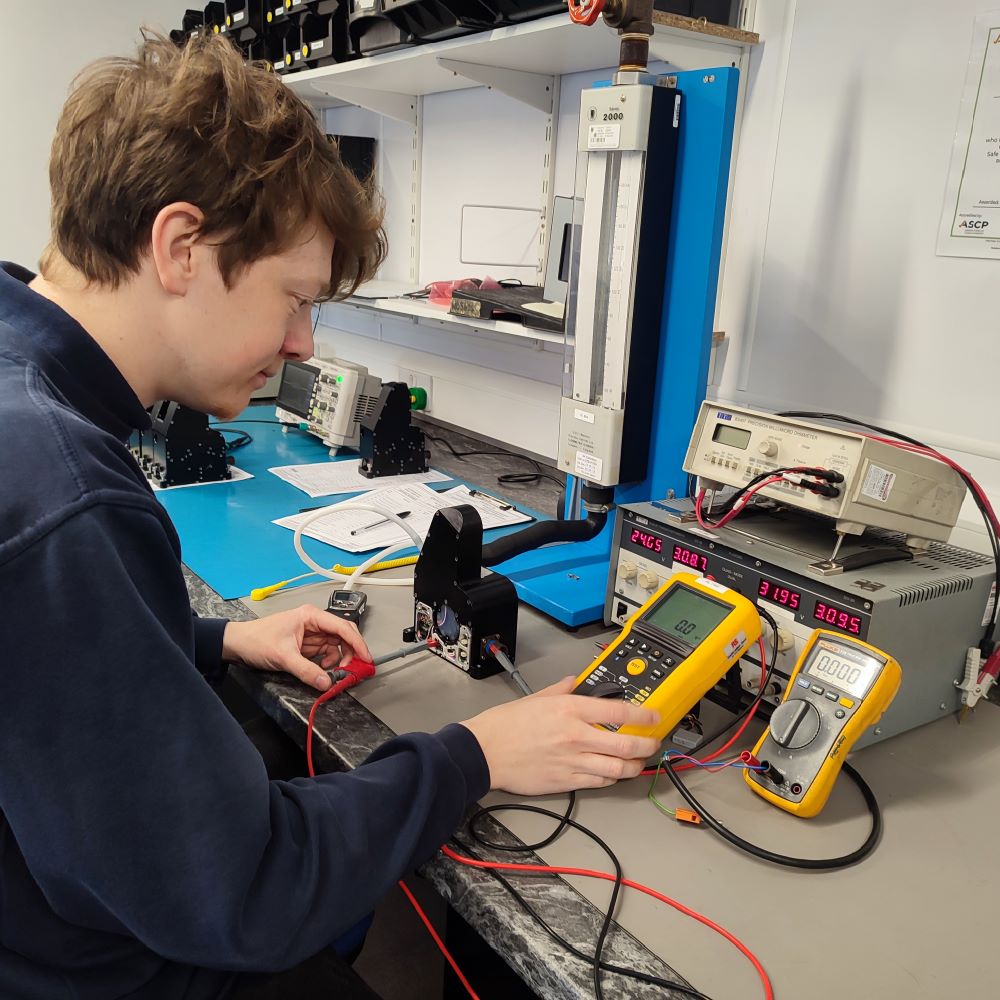

The specific requirements for ventilator respirators can vary depending on the type of military aircraft and its mission profile, so testing is crucial beforehand. Aircraft test sets can be used on many fast jet and rotary wing aircraft, from the Lynx to the Typhoon. Satisfying stringent design clearances demanded by the military aircraft specifications, and environmental type-testing to Mil Std 810F, and EMC to Mil Std 461 E.

Environmental chambers are also key to ensuring the success of ventilator respirators. Working to military standards on items such as Typhoon and F35 Lightning Ventilator systems, environmental chambers replicate challenging surroundings like temperature, humidity, and pressure to test product reliability and accuracy. If not otherwise tested, potential challenges could arise such as product failures, high-cost withdrawals and safety risks.

The effectiveness of respirator systems, however, lies in the proper training of military aircrew. Rigorous training includes the emergency protocols for respirator use and routine maintenance. Integrating respirator use into Crew Resource Management (CRM) ensures that all crew members are proficient in their operation and can work effectively together in emergency situations.

Looking to the future of aircrew protection

Ventilator respirators play a vital role in ensuring the safety and security of military aircraft pilots. They provide aircrew with the confidence to operate in hostile skies, knowing they have a critical layer of protection against a range of invisible threats.

The field of aircrew respiratory protection is constantly evolving. Research and design are focused on creating lighter, more comfortable, and more effective systems. Future advancements may include smart filters that can detect specific threats, seamless integration with digital displays and physiological monitoring, and enhanced communication capabilities.

As technology continues to advance and the challenges facing military aviators evolve, the importance of these sophisticated respiratory protection systems will only continue to grow.

Our expertise in precision manufacturing and advanced material integration contributes to the development and assembly of critical components for these sophisticated respirator systems, ensuring the safety of modern aircraft.

Discover Castlet’s Mk.8 and Mk.9 ventilator respirator systems today.