My Castlet Stories – From Service to Sales: Ed Everett’s Journey at Castlet

This month, we welcomed Ed Everett into the Sales team, as he steps into the role of Technical Sales Manager.

Ed has worked at Castlet for 12 years, where he has gained vast experience in engineering and servicing. Now, he’s putting this technical experience into practice as a Technical Sales Manager, travelling across the globe to help our customers find solutions to their problems on site – whether that’s outdated equipment or needing a new operational system.

We sat down with Ed to discuss his journey with Castlet and find out his plans for embracing his new role.

Ed’s story is the third instalment in our blog series ‘My Castlet Stories’ where we dive into the experiences and insights of our team.

To begin with, what is your role at Castlet and what does it involve?

After moving to sales as Technical Sales Manager, I work with our customers to help them find solutions to their problems on site, whether that’s outdated equipment or needing a new solution.

That involves getting stuck into the detail of the project, researching and understanding how things are working there and how it can be improved, and then building it from there.

Since my background’s in service, I’m used to various types of plant and working on a range of our equipment. I was doing that for the last eight years, since 2017. I want to try and play to my strengths with that, because I know the equipment. I know what it looks like and what can and can’t work.

And what inspired you to start your role at Castlet? How did you discover the firm?

Lots of people in my family and friends have been engineers or had technical careers, including diesel engines and steam locomotives, laser cutting, PCB manufacturing… I would hear a lot about it growing up, so I knew I wanted to explore a career in engineering.

I originally applied to work at Castlet as a draftsperson, and someone else applied to be a workshop technician at the same time. Somehow, we ended up in each other’s roles, with me in the factory and them in the office. But I think it worked out the best for both of us!

How was your role in Production?

I enjoyed it, and it was a great step towards what I wanted to do in future. I started building the equipment (control cubicles and transformer rectifiers), and then I moved to electronics in the cleanroom for a couple of years. And then the opportunity came up to shadow one of test engineers in the factory, who also travelled a lot. At that point I was just coming to the end of the college year, and they said, you can either continue with college or you can start travelling and getting real world experience first-hand. So I thought let’s go!

I travelled with my friend and Castlet legend Tony, who’s been with Castlet for about 40 years. I started shadowing him, then going out on my own, and then more recently training up the two newer site and service staff. It’s been very rewarding great experience throughout all of the different stages.

Looking back, I’ve really grown since starting – Castlet does, and always has, provided good career paths for employees.

And what would you say is your expertise in the industry now?

Fault finding and tricky troubleshooting is usually what I get called in to do. That’s normally when I get a phone call! My area of expertise is power and control products for Electrostatic Precipitators (ESPs) – mainly high voltage DC power supplies and control centres. I’ve acquired technical knowledge over the years, working with our transformers and equipment.

Now, I also help clients with how they’re running their plants and identify opportunities that could have an impact on their other systems. My experience has taught me wider knowledge about plant operations, so it’s very useful to be able to see as much of the bigger picture as possible.

And do you install the equipment too?

Yes, so I focus on installation, commissioning, file finding, maintaining, all sorts of things. My job is really varied. As I come from a service background, I draw a lot on that experience.

You’ve been on quite the journey so far at Castlet. What are you looking forward to in your new sales role?

Just being in this position for a few weeks, I have obtained a lot more of the technical information, working closely with clients. I’m seeing even more context, which I really enjoy. I love researching, asking questions, and getting to the bottom of things.

Even though I’ve been here at Castlet quite a while, it’s something new and challenging – no two days are the same. Moving into sales was also about being a bit more rooted for the future, without losing that connection to the plant room.

What do you like about working at Castlet?

As we’re a small company, everyone’s aware of what other people are working on, and lots of people have varied experience. We’re always bouncing ideas off each other when we’re on site to identify what’s happening, come up with ideas and find a solution. It feels like a real team that’s supportive – you couldn’t do the job without sharing knowledge. I’m grateful for the wealth of knowledge around me! There’s always something new to solve, and it’s never boring.

Looking back, do you have a rewarding or memorable moment in your career to date?

Most memorable would be my first solo visit. I was going to Mexico to install a large amount of equipment. I was still quite green, and it was my first time travelling anywhere near that far abroad.

I was needed for a turnkey project for a containerised switch room. It was a 50 ft container full of control panels and cabinets that were all connected to a variety of equipment around the plant, transformers and motors etc. It was my role to supervise the local team and make sure that the installations went well – which they did! This first trip definitely gave me the travel bug.

Do you get to travel all over the globe?

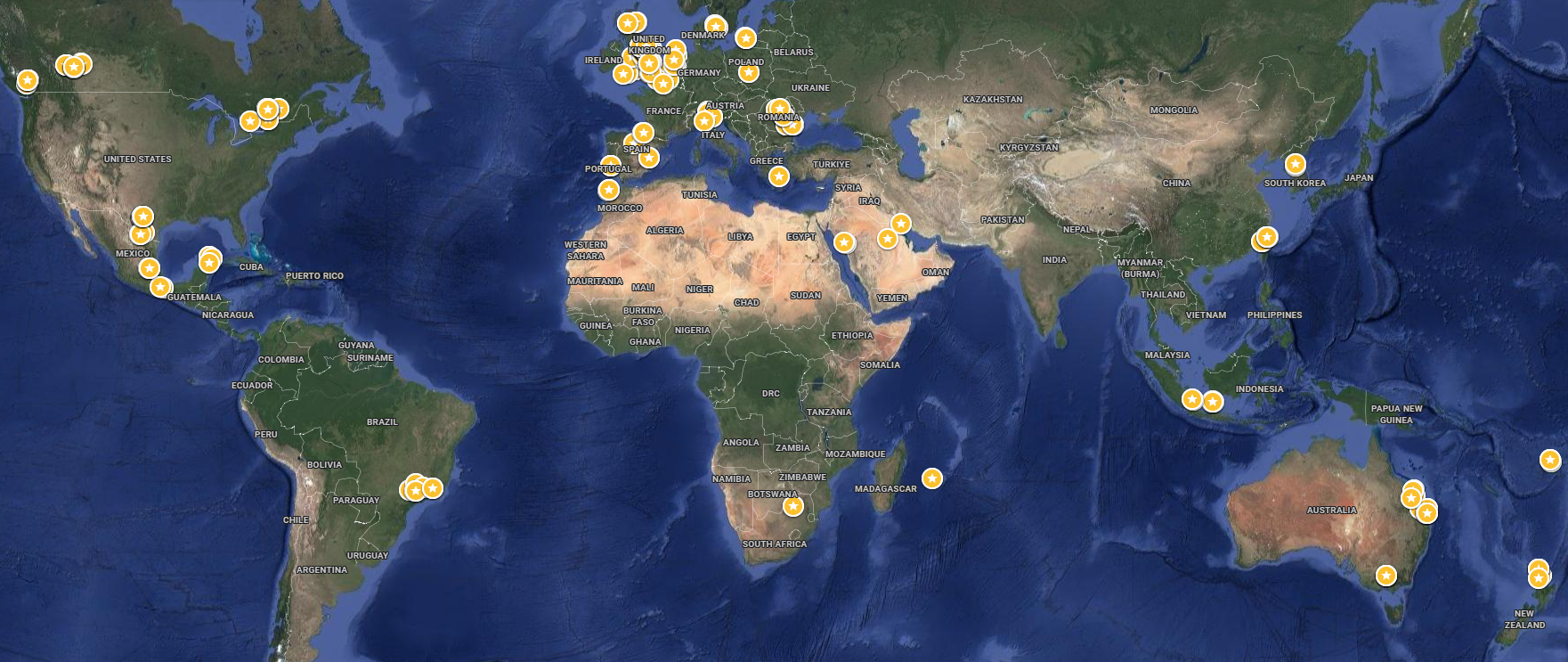

I do, and I try and keep a tally… I’ve been to 26 countries with Castlet.

Wow! Do you get to see the countries or is it all work, work, work?

Some trips can be – airport – hotel – work – hotel – airport. But then, sometimes you get a few days off and can explore a little. I tended to do the longer trips, like four, six, eight weeks long. So with that, you get more opportunity see the country and meet more people. One place still on my bucket list is Antarctica. Maybe one day I’ll figure out how to get there!

2019 was the busiest year for me. On one long-haul flight I calculated that I spent about seven months out of the country in calendar days. That included a month in Brazil.

COVID changed things though, pushing us into remote work for a while. Different countries reopened at different times, but over the last couple of years, things have mostly gone back to normal from a working perspective.

What makes us different is the rhythm—we tend to do shorter, more frequent trips. I might have spent Monday to Thursday in France, come back for the weekend, then head out to another site the following week. It keeps things varied and fast-moving. We know it’s important to be present on-site, which is why we travel all over the world, sometimes even at very short notice.

What would you say sets Castlet apart?

For me it’s our versatility. Most of our equipment is bespoke, tailored to what our customers need. We have a standard set of equipment and a standard design, but every project is different due to the differing needs of the client. It’s extremely rare that we’ll ever say no to a client.

Our clients come to us, and we find them a solution, for whatever the challenge is. We have expertise in control systems – controlling circuits, logic circuits, and motor control centres.

What are your predictions for the future of the industry?

I want to start by catching up on upgrades and maintenance for the plants that we work with. They need maintenance to handle challenges from the necessity to reduce emissions. Although there’s a lot of focus on the coal/fossil fuel industries, we see work in glass, asphalt, tarmac, lots of different industries needing our equipment.

We supply upgraded technology and new ways of working, helping to keep their equipment running. The service side of things will only grow stronger as the equipment will always need maintaining.

And when you’re not travelling the world or working on an ESP solution, what can we find you doing?

Probably eating tacos al pastor – this is a bit of a callback to my first work trip as I discovered them whilst revisiting that area in Mexico. It’s a pork taco with a delicious marinade of pineapple and different spices. I say I discovered them, but actually it was introduced to me by my now wife who I met in that same town. Good memories in Mexico!

Other than that, I play guitar, have done for 20 years – recently formed a new band and we had our first gig last month. Definitely a good show for people who like a variety of music genres!

Thanks Ed for taking the time to take us through your Castlet journey. The next instalment will see Ian Melton, Business Development Director talk to us about starting as an electrician, what makes Castlet Castlet and his new favourite hobby: beekeeping!

At Castlet, we’re always trying to find a solution to solve your engineering challenges. Get in touch with Ed and the team today to find out how we can help you with bespoke ESP power and control solutions.